There is a misunderstanding that slows many industrial transformations: thinking that “using AI” is the goal. It is not. The goal is a factory that can run well under real conditions—with stable quality, predictable performance when the product mix changes, energy under control, and operations that keep going even when the context becomes difficult.

That is why the term Factory 5.0 is appearing more often in leadership conversations. It brings the discussion back to where value is created: the shop floor. But for the term to be useful, it must be grounded in the right reference. In the European Union’s approach, Industry 5.0 does not replace Industry 4.0. It complements it and expands the objective beyond efficiency alone, clearly including sustainability, resilience, and human-centricity.

In this sense, “Factory 5.0” is the operational translation of the same ambition: how manufacturing is designed and managed when technology performance and broader impact must improve together.

Over the last decade, many companies invested in digitalization, automation, and efficiency. Those investments still matter. What changes now is the competitive baseline: the differentiator becomes system reliability.

Factory 5.0 is the move:

When a system is reliable, KPIs improve with less volatility. When it is not, results come in waves: a pilot works, then fades; a use case starts, then gets stuck; a model performs, then degrades. Factory 5.0 is about avoiding that pattern—by treating AI as an industrial capability, not a sequence of experiments.

Industry 5.0 is built around three pillars: human-centricity, sustainability, and resilience.

They can sound abstract, but they are very practical if used as decision criteria.

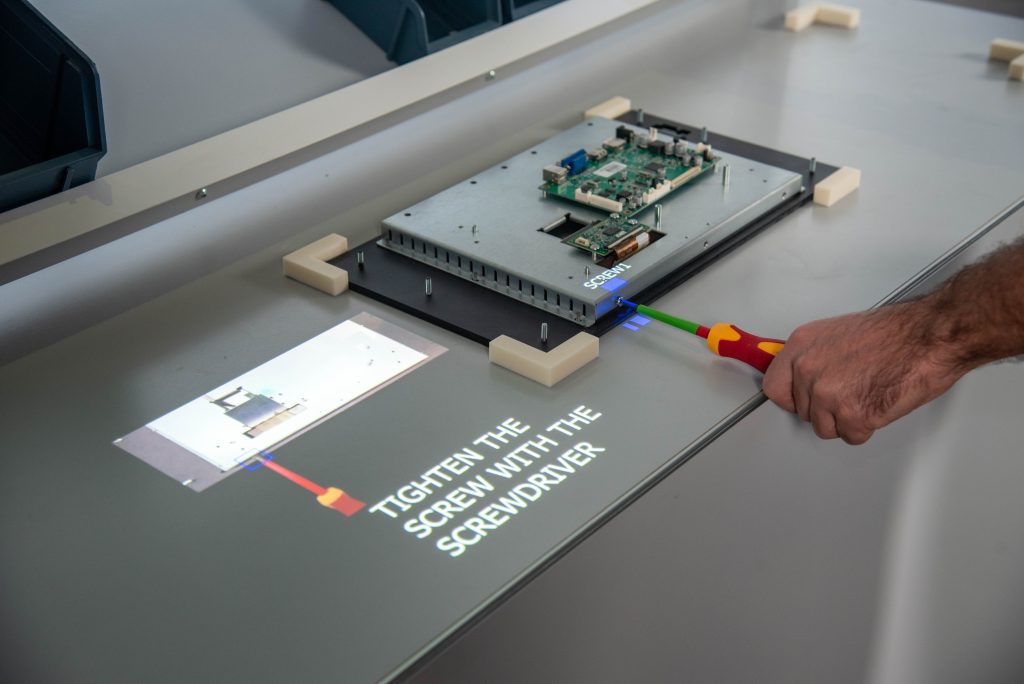

A solution is not successful because it looks good in a demo. It is successful when it makes work clearer, safer, and more repeatable on the line—reducing errors, rework, and stress. The European framework explicitly highlights worker wellbeing and the need to respect privacy, autonomy, and dignity.

On the shop floor, this means solutions that guide, train, and support operators—not solutions that add complexity.

In manufacturing, sustainability shows up in daily numbers: scrap, rework, energy per unit, process stability. AI creates value when it becomes a measurable lever for resource efficiency—less variability, less waste, and better control.

Resilience is the ability to absorb shocks and volatility without losing quality and reliability—across supply chain, maintenance, safety, and cyber risk in connected environments.

It is a management topic before a technology topic: it is about designing the system so it does not break when conditions change.

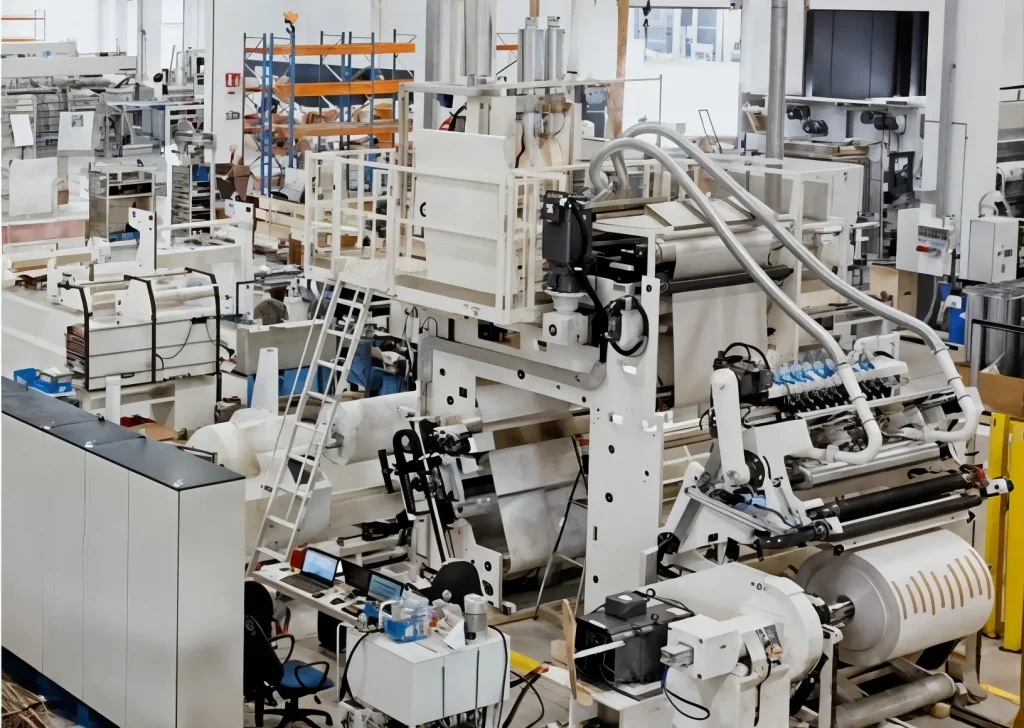

Every efficient plant is optimized around its own balance: layout, equipment, skills, safety constraints, quality targets, and takt time. That is exactly why AI cannot be treated as a standard IT rollout. If AI is meant to improve operations, it must be integrated with industrial discipline.

In most cases, credibility on existing assets depends on three fundamentals:

When these elements are missing, a model may “work” but it will not last. When they are in place, AI becomes part of how the factory runs.

The most important frontier is not desk-based AI. It is intelligence applied where value is created: machines, stations, flows, and operators. Here AI is not a dashboard; it is operational support that senses signals, detects anomalies, and guides decisions in real time.

In a Factory 5.0 strategy, the strongest use cases are those that improve KPIs and strengthen operational stability:

The goal is not to “have use cases”. The goal is to turn them into repeatable capabilities that can scale across lines and plants.

At e-Novia, we help companies make AI a concrete industrial lever through an end-to-end approach: setting technology priorities, integrating solutions on existing assets, and supporting industrialization and scaling. The aim is to build AI in manufacturing and physical AI solutions that people can adopt, that remain robust over time, and that deliver measurable results on operational KPIs.

When a technology developed in-house (or through partnerships) has the characteristics of a replicable asset—IP, a product, or a platform—the Venture Studio supports commercialization and value capture: go-to-market paths, industrial partnerships, and—where relevant—dedicated initiatives to monetize innovation.

Not exactly. Industry 5.0 is the European framework that complements Industry 4.0 and broadens the objective beyond efficiency alone, explicitly including sustainability, resilience, and a human-centric approach.

Factory 5.0 is a useful way to translate that intent into plant reality: where decisions become concrete and measurable—process, people, quality, energy, and operational continuity.

It is rarely about finding a “more advanced” model. It is about fundamentals and management. If data is not reliable and readable in process context, AI becomes noise. If OT and IT are not integrated in a structured way, scaling becomes fragile. And if governance is missing—monitoring, drift handling, ownership, and change management—performance degrades over time. When these foundations are in place, AI becomes an industrial capability rather than a demo.

The most solid ones are those that improve KPIs and make operations more stable. Vision-based quality inspection often delivers quickly because it directly reduces scrap and rework. Predictive maintenance strengthens continuity and resilience. Operator-assist AI improves standardization and adoption because it works with people, not around them. Process and energy optimization ties productivity and sustainability to daily metrics. The right move is not to maximize the number of initiatives—it is to select the ones that can stay in production and scale.

Discover how e-Novia supports companies through Innovation Consulting and the Venture Studio to adopt AI in manufacturing and physical AI, integrate them into operations, and scale them sustainably on the shop floor