In recent years, artificial intelligence has moved from being a purely experimental topic to becoming a concrete lever for transforming business processes. Adoption is accelerating in highly digitalised sectors, driven by increasingly accessible tools and by the need to increase productivity and efficiency. At the same time, however, a fundamental part of the economy – based on physical products, plants, infrastructures and industrial processes – is evolving more gradually and with greater complexity.

Artificial intelligence in manufacturing sits exactly at this intersection. On one side, interest from companies is clearly growing. On the other, integrating AI into physical systems requires engineering expertise, analytical capabilities and a structured method to govern complexity. It is not about adding another piece of software on top of what already exists: it is about rethinking how machines operate, collect information and interact with people and processes.

LinkedIn’s Future of Work Report indicates that 55% of roles are expected to change significantly by 2030, and that manufacturing is among the sectors most exposed to this transformation. The rising demand for AI-related skills in technical and operational roles confirms that companies are aiming for a step change. Yet many still struggle to turn this interest into concrete, scalable initiatives that create real value in physical environments.

In this scenario, artificial intelligence in manufacturing can become a decisive competitive factor – not as a technological exercise, but as a way to see what is currently difficult to observe, anticipate critical conditions, improve operational decisions and design products and systems that are both more efficient and safer.

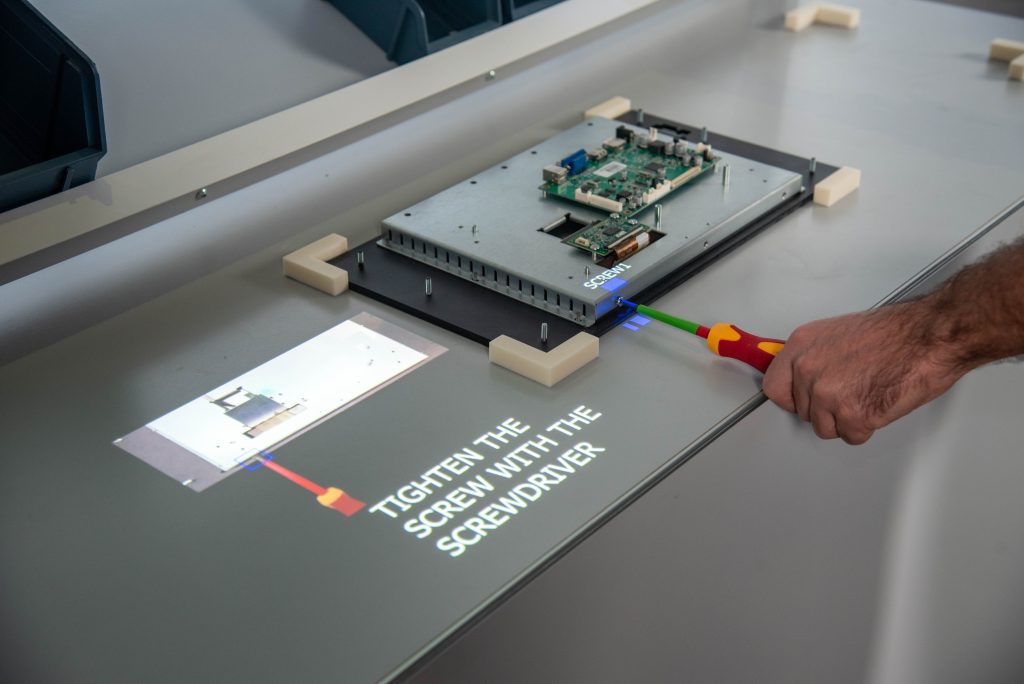

Today, many companies are already using AI-based digital solutions, especially for structured data, performance analytics or administrative processes. However, applying AI to physical systems requires an additional step: embedding the ability to observe and interpret what is happening inside products, machines and production lines.

This transition is not immediate. Three dynamics are particularly relevant:

Despite these challenges, more and more companies regard industrial AI as a strategic priority. This is partly because technologies are becoming more accessible, and partly because global competition is accelerating in the adoption of solutions based on advanced analytics, decision-support systems and more sophisticated automation.

AI can take different forms inside a factory or product. What all mature applications have in common is the ability to provide useful, reliable and timely information about what is happening in the physical world.

The most relevant application areas include products that can report back on how they behave, processes that become more stable over time and production lines that react more precisely to changing operating conditions.

A growing number of companies are integrating AI into their products or components. This makes it possible to:

What distinguishes an intelligent product is not how many technologies are embedded in it, but its ability to interpret what is happening and turn that into information that is truly useful for those who use or manage it.

Artificial intelligence in manufacturing is particularly effective in processes that must remain stable and consistent over time. In these contexts, AI can:

The goal is not to fully automate the factory, but to provide better visibility of what is happening and enable operators to make more informed decisions.

LMaintenance is one of the areas where AI has already proved its value. When machines and components can detect abnormal conditions and indicate how a phenomenon is evolving, it becomes possible to intervene before a failure occurs.

In these cases, predictive maintenance can:

The main difference compared with traditional models is that predictions are based on what is actually happening in production, rather than on assumptions or statistical averages.

Integrating artificial intelligence in manufacturing is not a linear process. Technology is crucial, but not sufficient. What often determines the success or failure of a project is the ability to align skills, processes and objectives, ensuring that every step – from idea to production – is handled with rigour.

The main sources of complexity can be grouped into three aspects:

For these reasons, a progressive, multidisciplinary and engineering-driven approach is essential.

Experience in complex industrial projects shows that adopting AI in physical systems requires a clear path that accompanies companies from exploration to production.

The e-Novia method is structured into three complementary phases.

Questa fase ha l’obiettivo di identificare applicazioni ad alto valore, tenendo conto sia delle esigenze operThe goal of this phase is to identify high-value applications, taking into account both operational needs and the company’s strategic direction.

Typical activities include:

The outcome is a clear view of the opportunity space and a prioritised set of initiatives to activate.

Once opportunities have been identified, the next step is to design solutions that allow products and processes to acquire new capabilities.

This phase may include:

The objective is not to introduce technology for its own sake, but to provide tools that genuinely improve process quality, efficiency and continuity.

The move to production is the point at which the solution must demonstrate robustness, reliability and scalability.

This phase typically includes:

The outcome is an industrialised solution, ready to be used by operators, technicians and customers.

When artificial intelligence in manufacturing is introduced through a structured method, the effects can be substantial:

AI does not replace people; it expands what they can do. It provides tools that help them make faster, better-founded decisions and manage complexity more effectively.

What are the main applications of artificial intelligence in manufacturing?

The most relevant applications are those that improve quality, stability and visibility of industrial processes: advanced monitoring, predictive maintenance, better control of production parameters and solutions that help operators and engineers make informed decisions.

What capabilities are needed to introduce AI into physical systems?

Industrial AI requires a coordinated set of capabilities: a deep understanding of manufacturing processes, the ability to design appropriate observation and sensing systems, and skills to embed intelligent functionalities into machines, components and production flows.

Why do many projects fail to move beyond the prototype stage?

Often because key elements are not considered from the beginning: robustness, integration with existing systems, data quality, operational continuity and industrialisation. A model may work in a controlled environment but not be ready for the complexity of a real plant.

How can a company start its AI adoption journey in manufacturing?

By first identifying the phenomena that matter most for quality and continuity, and assessing whether the necessary data and conditions are in place. From there, a structured process can guide the company through opportunity assessment, solution design and transition to production.

Discover how e-Novia supports companies and innovation leaders in bringing artificial intelligence into manufacturing through structured pathways and Physical AI solutions that are ready for real-world production environments.